TransFueler Aviation

America's premier aviation refueler.

In use with most major aircraft manufacturers and a wide range of operators; Fixed Wing, Unmanned (UAV) & Helicopter.

- Tank Capacities Available: 110 - 2500 Gallons

- Tanks are Fully Baffled, Stainless Steel or Aluminum.

- DOT 406 or UN31Y Tanks are Also Available.

- All Piping, Fittings Hoses & Hardware are Aviation Fuel Rated & Compatible.

- Fuel Sump Drain Valve for Daily Water Check

- Fuel Level Gauge

- Ball Valve to Isolate Tank

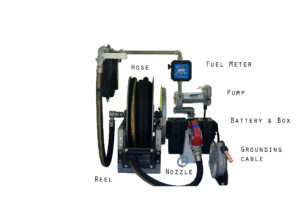

- GPI M-3025-AV-PO 12V High-Output 25 Gallon Per Minute Pump

- 12V Battery

- 115V 7.2A Automatic Charger Battery Box

- 50’ Certified Aviation Hose, Meets API Bulletin 1529, NFPA 407

- Hannay Stainless Steel Spring Rewind Hose Reel, Aviation Approved Internals

- Velcon or Facet Aviation Fuel Filter w/Filter Mount

- Mechanical Totilizing Meter

- 10” Betts Fill Port w/ Integral 2” Normal and Emergency Vent

- 50’ Static Grounding Cable on Reel

- OPW or EBW Aviation Overwing Nozzle w/ Dust Cap w/6.5’ Grounding cable.

- Super-Duty Steel Chassis

- Steel Fenders & Diamond-Plate Decking

- Tandem Axle

- Electric Brakes with Safety Breakaway System

- LED DOT Lighting, with Steel Guards

- Adjustable Ball Hitch W/Safety Chains

- Heavy-Duty Jack

Additional Options

TransFueler has a wide variety of options. We can equip your TransFueler to precisely match your needs:

- Hose Length Options Up To 150' of UL Hose on Reel

- Double-Wall Stainless Steel or Aluminum Tank

- DOT 406 Tank

- UN31Y/A Tank

- Single Point Fueling Nozzle

- Pump Options: 12V, 115VAC, Ultra-High Output, Diesel Powered or Gas Powered Pumps

- Certifiable Meter; For Resale of Fuel, TCS or Liquid Controls

- Piusi Fuel Management System; To Control and Track Fuel Dispensing

- Refuel / Defuel System. Great option that allows the pump to pull fuel out of a tank as well as dispense it. A TransFueler EXCLUSIVE

- Vapor Recovery System, Stage I

- Fire Extinguisher(s), Mounted

- Bottom Fill Kit w/2" Dry Disconnect, 2" Ball Valve & Sump Drain

- Spare Tire Assembly w/Mount

- Tool Box: 48" or 58"

- Locking Steel Enclosure Cabinet; Secures Dispensing Equipment

- Work Lights; LED or Halogen

- Solar Panel System: 60 Watt, Includes Controller

- Air Compressor

Looking for something not included above? Contact us with your needs: 1-800-994-TANK

A specific tank is required per CFR49 Parts 100 - 185 transportation, for the transport of gasoline in a bulk container. Due to the flash point of gasoline, this tank falls into the category of Class III Fuels that is REQUIRED to be transported in a Code DOT 406 vessel. If this tank will hold gasoline, the tank is required to meet DOT 406 Specifications, be labeled accordingly and be annually tested per CFR 49 requirements. Gasoline has a Flash Point of -40`F, which is lower than the 100`F for Class III Fuels to be included in the “non-code” section of this provision for Class III Fuels.

DOT406 Tanks meet the requirements of 49 CFR Ch. I (10-1-07 Edition) §172.102, B1 and 49 CFR Ch. I (10-1-07Edition) §173.242,Bulk Packaging for Certain Medium Hazard Liquids and Solids, including solids with dual hazards.

DOT406 specification tanks meet Federal regulations for the transport of Gasoline and most other fuels over public roads.

Important DOT 406 Requirements (not inclusive of all DOT 406 specifications):

MANWAY

The standard manway incorporates a 10” fill/inspection port and also functions as an emergency valve. The manway also incorporates a “normal” valve that opens to accommodate for changes in vacuum and pressure per the DOT code. Depending on tank dimensions, a smaller manway with the vents and ports is installed and a larger bolted manway is added for full inspection access.

CONNECTIONS / INTERNAL VALVE

All connections on top of the tank are shielded by rollover protection rails. All connections to the base of tank are done with emergency valves that feature an externally operated, internally actuated poppet, external shear section, and fusible link (closes in case of fire), all per the DOT code.

MATERIALS

Tanks are constructed of A36 mild (carbon) steel, 304 stainless steel, or aluminum alloy. The shell and head thicknesses are dictated by the DOT/ASME code and are based on the material used and the dimensions of the tank.