TransFueler M-Series

The TransFueler M-Series Advantage

NO HAZMAT? NO PROBLEM...

DOT Regulations allow for up to 119 gallons of any commonly used fuel (Including Gasoline) to be transported virtually anywhere, without the need for a Haz-Mat license. Gas must be transported in a tank bearing a DOT Special Exemption. Diesel & Jet Fuel may be transported in a non-specification tank. The M-Series complies with this law, allowing our customers to safely and legally transport fuel without the need for a Haz-Mat license.

Our patent-pending system consists of a number of 119 gallon non-connected tanks. We have developed a unique dispensing system using a single pump, accessing any of the tanks by way of a jump hose and quick-connect fittings. Simply connect the jump hose to whichever tank you choose, and dispense fuel. Safe. Convenient. Legal.

- Save Money: Fuel your equipment or vehicles at your convenience. No time wasted waiting for fuel trucks. Fuel on your schedule...

- Save Money: Fuel your equipment or vehicles where you need to. In the field. On the jobsite. At remote locations. Virtually anywhere!

- Save Money: TransFueler M-Series tough construction lasts far longer than typical flimsy truck bed tanks. Built to last under hard use.

- Delivered ready to use. Fill & GO!

Standard Equipment

- Standard Features

- Superior Engineered, 12 gauge Carbon Steel “V Bottom” Tanks

- Carbon Steel Platform, holds dispensing equipment

- Fork Lift Pockets & Lifting Rings

- Can have as many as 8, 119 gallon, carbon steel tanks

- Fuel gauge on each tank

- Vented fill cap on each tank

- Powder coat finish, in a wide choice of colors

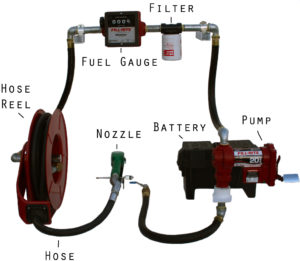

- GPI & Fill-Rite 12V High-Output 10 Gallon Per Minute pumps

- 12V Battery with Box

- Battery Charger

- 12’ UL Hose with Manual Shutoff Nozzle

- Fuel Filtration System

- Vented Fill Cap

- Emergency Vent

- Super-Duty Steel Chassis

- Steel Fenders & Diamond-Plate Decking

- Tandem Axle

- Electric Brakes with Safety Breakaway System

- LED DOT Lighting, with Steel Guards

- Adjustable Ball Hitch

- Heavy-Duty Tongue Jack

- Powder Coat Finish

- “Fuel Cart” style Available with Pintle Hitch

Revolutionizing Mobile Fueling!

Optional Packages

Includes Standard Dispensing Equipment Plus

- Fuel Meter

- Fuel Level Gauge

- Deep Cycle Battery Kit; w/Box and Automatic Charger

- Automatic Shut-off Nozzle & Swivel

- 25’ UL Hose on Spring Rewind Reel

- GPI or Fill-Rite 15 Gallon Per Minute Pump

Looking for something not included above? Contact us with your needs: 1-800-994-TANK

A specific tank is required per CFR49 Parts 100 - 185 transportation, for the transport of gasoline in a bulk container. Due to the flash point of gasoline, this tank falls into the category of Class III Fuels that is REQUIRED to be transported in a Code DOT 406 vessel. If this tank will hold gasoline, the tank is required to meet DOT 406 Specifications, be labeled accordingly and be annually tested per CFR 49 requirements. Gasoline has a Flash Point of -40`F, which is lower than the 100`F for Class III Fuels to be included in the “non-code” section of this provision for Class III Fuels.

DOT406 Tanks meet the requirements of 49 CFR Ch. I (10-1-07 Edition) §172.102, B1 and 49 CFR Ch. I (10-1-07Edition) §173.242,Bulk Packaging for Certain Medium Hazard Liquids and Solids, including solids with dual hazards.

DOT406 specification tanks meet Federal regulations for the transport of Gasoline and most other fuels over public roads.

Important DOT 406 Requirements (not inclusive of all DOT 406 specifications):

MANWAY

The standard manway incorporates a 10” fill/inspection port and also functions as an emergency valve. The manway also incorporates a “normal” valve that opens to accommodate for changes in vacuum and pressure per the DOT code. Depending on tank dimensions, a smaller manway with the vents and ports is installed and a larger bolted manway is added for full inspection access.

CONNECTIONS / INTERNAL VALVE

All connections on top of the tank are shielded by rollover protection rails. All connections to the base of tank are done with emergency valves that feature an externally operated, internally actuated poppet, external shear section, and fusible link (closes in case of fire), all per the DOT code.

MATERIALS

Tanks are constructed of A36 mild (carbon) steel, 304 stainless steel, or aluminum alloy. The shell and head thicknesses are dictated by the DOT/ASME code and are based on the material used and the dimensions of the tank.